Specifications of the adhesive backed rubber strips

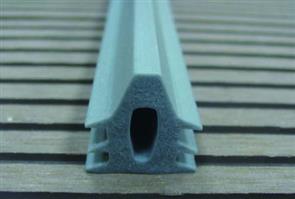

1) EPDM sponge rubber strip

2) with adhesive back

3) easy to install

4) Customized

Our production line utilizes our proven high quality seal designs with the addition of high-performance adhesive tape. These adhesive backed rubber strips are ideal for a wide variety of applications.

With this new bonding capability, the user can easily remove the protective tab and position the seal in place without the use of tools.

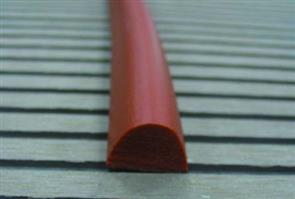

1)Material: EPDM, CR etc.

2)Size: Standard and customized sizes available.

3)Colour: Black

4)Application: Window brush, machine, plastic coated steel door and window, curtain walls, doors and windows

5)Feature: Extrusion products. Excellent chemical and physical property. Good resistance to aging. Good electrical insulation. High flexibility.

6)Well and high quality control

Product Description

The most common and by far the most important application of the EPDM based sealing system in an automobile is the door seal (co-extruded profiles). These are dynamic seals which seals the door with the door flange firmly to avoid dust, water & air to leak inside the cabin. The same sealing system is also used in deck lid sealing, bonnet sealing and similar other applications. The seals are also very important as far as aesthetics is concerned. It takes care of the door & Body flange panel variations and gives a smooth look from outside.

Functional parameters are easy fitment on the sash but high retention force after fitment and the desired level of force required in the closure of the door. The important design parameters like compression load deflection force, insertion and retention force are the reflection of these factors.

Features of the rubber strips:

* The obvious function is shockproof. To reduce (or even disappear) door slam

* Excellent heat insulation;

* Excellent sound insulation;

* Excellent sealed performance;

* The adhesive backed rubber strip can keep mosquito and other bugs out the door

* Perfect flexibility and anti-deformation, the ageing weather-resistant, resistant to ozone

The sizes, shapes and the colors can be customized.

Molded Rubber Product:

Professional factory to produce GF, GLT, GFLT rubber products with high quality & best price

1, Material: NBR, CR, SBR, EPDM, IIR, HNBR, ACM, NR, EP, SIL, FKM etc.

2, Hardness: Between 30~90 shore A

3, Property: High/low temperature resistance, oil and fuel resistance, water resistance, weathering resistance, Ozone resistance etc.

4, Certification: ISO9001: 2008, RoHS, FDA

5, Packing: Plastic bag&carton box or according to your requirements.

6, Application: Automotive, Industrial, Medical, Agricultural etc.

7, According to your drawings or samples.

8, OEM or ODM is welcomed.

Capability of our rubber workshop:

1. ISO9001: 2008 certificated factory.

2. Mix materials in house professionally. And we have our own mold workshop.

3. 20 sets of compression machines and 2 sets of injection machines to run mass production.

4. 2 sets of advanced trimming machines to assure non-flash products.

5. 20 QC technicians and 6 R&D engineers, strict quality control and assurance system to assure high quality of the adhesive backed rubber strips.

6. Lead time: 3~10 days.

7. High efficient management to achieve the production cost optimization.

8. OEM and ODM are highly welcomed.